Description

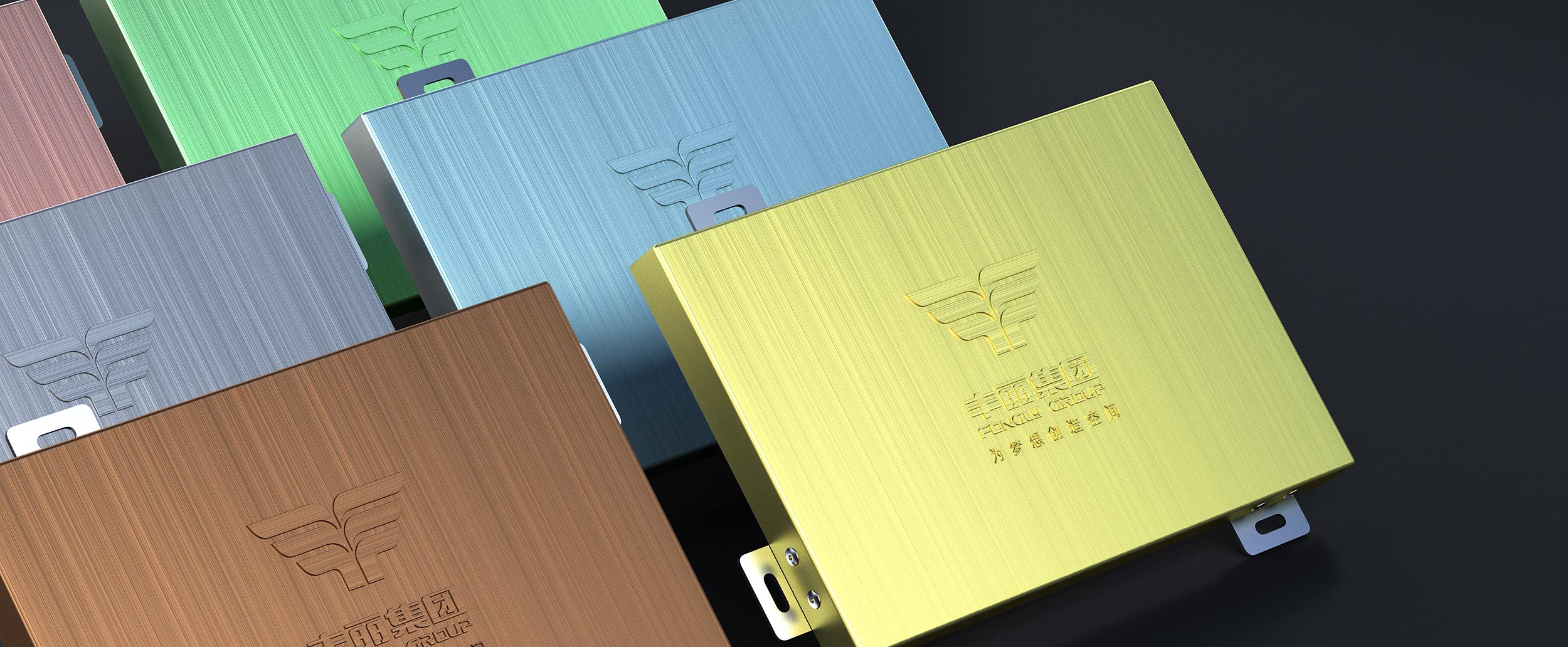

Surface brushed aluminum veneer is a metal decorative material that uses aluminum alloy plate as the base material and forms a fine texture on its surface through a special treatment process. The following is a detailed introduction to surface brushed aluminum veneer:

1. Materials and properties

Material: The surface brushed aluminum veneer is made of aluminum alloy sheet. This material has excellent characteristics such as light weight, high strength and corrosion resistance.

Features:

l Beautiful texture: Through the wire brushing process, the surface of aluminum veneer presents a unique metallic texture and delicate texture, which increases the visual beauty.

l Strong durability: The surface brushing treatment not only improves the decorative effect of aluminum veneer, but also enhances its wear resistance, scratch resistance, corrosion resistance and other properties, prolonging the service life.

l Easy to process: Aluminum alloy materials have good processability and can be cut, bent, welded and other processes as needed to meet the needs of different shapes and sizes.

l Environmental protection and safety: The surface brushed aluminum veneer will not produce harmful substances during production and use, meets environmental protection requirements, is not easy to burn, and is safe and reliable to use.

2. Application areas

Surface brushed aluminum veneer is widely used in many fields because of its unique texture and excellent performance:

l Architectural decoration: such as building curtain walls, ceilings, wall decorations, etc., to enhance the visual effect and aesthetics of buildings.

l Home appliances: used for surface decoration of refrigerators, air conditioners, ovens, microwave ovens and other home appliances to improve product grade and texture.

l Vehicles: The interior and exterior decoration of vehicles such as airplanes, automobiles, high-speed rail, etc. takes advantage of their lightweight, high strength, corrosion resistance and other characteristics.

l Other fields: such as chemical packaging, suitcases, gift boxes, lighting, electronic product shells, etc. to meet diverse decoration needs.

3. Production process

The production process of surface brushed aluminum veneer mainly includes the following steps:

l Aluminum plate pretreatment: Clean, remove oil, remove rust and other treatments on the aluminum plate to improve surface cleanliness and adhesion.

l Spraying: Spray primer, topcoat and other coatings on the surface of the aluminum plate to form a uniform coating.

l Wire drawing treatment: Use mechanical or electrochemical methods to draw the surface of the coating to form a fine texture.

l Surface treatment: Seal, clean, dry and other treatments on the brushed aluminum veneer to improve the corrosion resistance and wear resistance of the surface.

4. Advantages and weaknesses

Advantages:

l The texture is beautiful and the decorative effect is good.

l Strong durability and long service life.

l Easy to process and install.

l Environmentally friendly and safe, meeting the requirements of modern architectural decoration.

Inadequacies:

l Compared with ordinary aluminum veneer, the processing cost of surface brushed aluminum veneer may be slightly higher.

l Care should be taken to avoid scratching or damaging the surface texture during installation and maintenance.

5. Famous cases

Surface brushed aluminum veneer has been used in many famous buildings and projects, such as Sydney Opera House, Shanghai Tower, etc. These cases not only demonstrate the aesthetics and practicality of surface brushed aluminum veneer, but also reflect its important position and value in modern architecture.

To sum up, surface brushed aluminum veneer is a metal decorative material with unique texture and excellent properties. It is widely used in architectural decoration, household appliances, transportation and other fields. With the continuous development of modern architecture and design concepts, the application prospect of surface brushed aluminum veneer will be broader.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)